When it comes to DTF (Direct to Film) transfers, one small choice can make a big difference: hot peel vs. cold peel. At Gemini Design Co, we help creators, brands, and print shops get the best-looking results possible, and understanding this difference can seriously upgrade your workflow. Both options deliver vibrant color and durability—but how and when you peel the film changes speed, finish, and overall production efficiency.

Hot peel DTF is all about speed and momentum. With hot peel, the film is removed immediately after pressing—no waiting required. This makes it a favorite for high-volume production and fast turnarounds. The result is a smooth, flexible finish that’s perfect for athletic wear, fashion tees, and on-demand orders. If efficiency and flow matter to your business, hot peel keeps things moving without sacrificing quality.

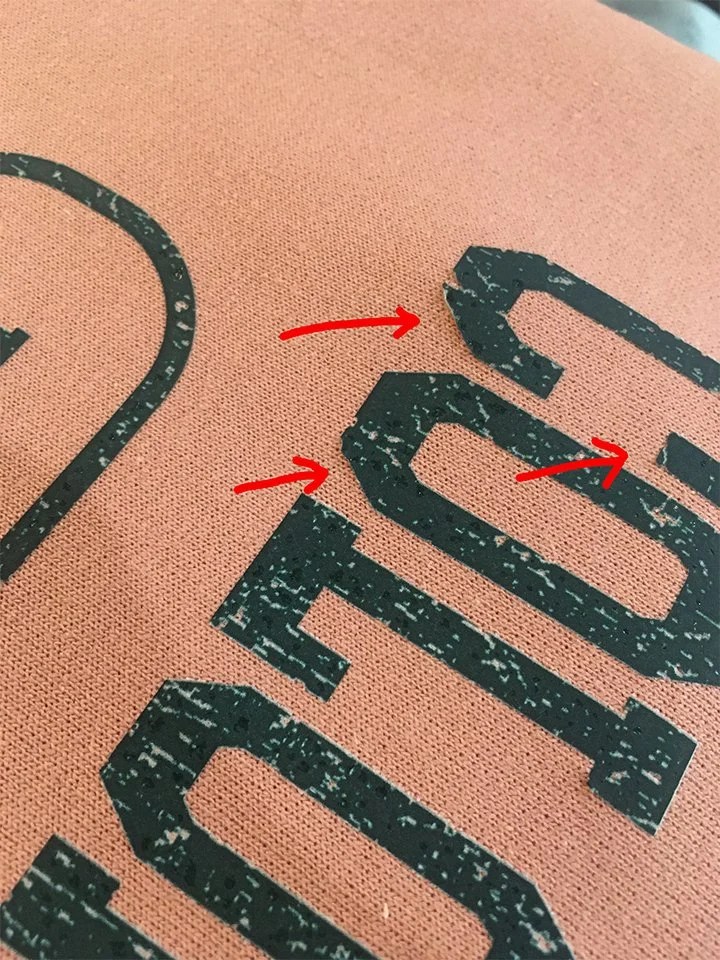

On the other hand, cold peel DTF is the go-to for maximum detail and a premium feel. After pressing, the transfer must cool completely before peeling, allowing the adhesive to fully set into the fabric. The payoff? Sharper edges, a slightly thicker hand feel, and exceptional durability. Cold peel is ideal for intricate logos, bold graphics, and garments where longevity and polish are top priorities.

So which one should you choose? The answer depends on your goals—and that’s where Gemini Design Co shines. We offer expert guidance and top-tier DTF solutions tailored to your production style, whether you’re chasing speed, detail, or both. Ready to elevate your prints and impress your customers? Let Gemini Design Co help you peel back the difference and press with confidence. 🚀

Leave a comment