If you’re dealing with DTF prints peeling or cracking, you’re not alone—and the good news is that these issues are almost always fixable. At Gemini Design Co, we hear this question often from apparel brands and print shops getting started with DTF printing. Peeling and cracking usually aren’t random problems; they’re signs that something in the process needs adjustment, from curing to pressing technique.

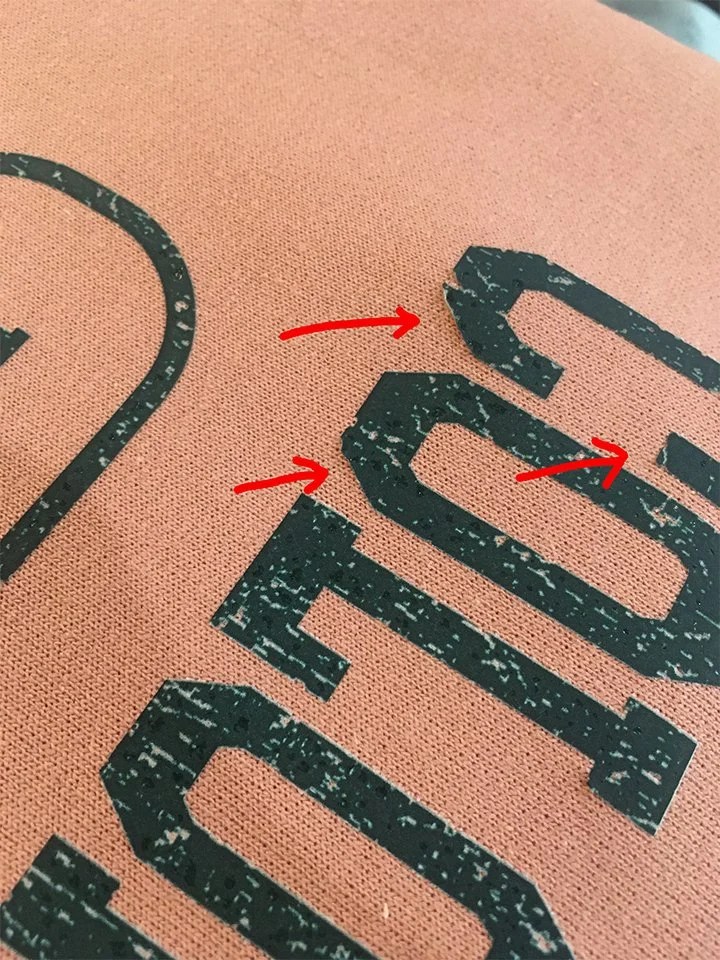

One of the most common causes of peeling DTF prints is improper curing of the adhesive powder. If the powder isn’t fully melted before pressing, it won’t bond correctly to the fabric. On the flip side, overheating the powder can weaken adhesion and cause cracking over time. The fix? Make sure your powder reaches a smooth, slightly glossy finish during curing—no grainy texture and no scorching.

Heat press settings are another major factor. Incorrect temperature, pressure, or press time can all lead to cracking or edge lift after washing. Too little pressure prevents full adhesion, while too much pressure can damage the print’s flexibility. For best results, use firm, even pressure, follow recommended temperature ranges, and allow the garment to cool before peeling the transfer film (unless you’re using hot-peel film).

Finally, don’t overlook materials and handling. Low-quality film, expired adhesive powder, or moisture in your workspace can all affect durability. Always pre-press garments to remove moisture and wrinkles, and use quality supplies designed for DTF printing. If your prints are peeling or cracking, small tweaks can make a big difference—and Gemini Design Co is always here to help you dial in your process so your custom apparel looks great and lasts wash after wash.

Leave a comment